Up to this point 35 years of development had gone into the Small Block Chevy. Right from the start the small block proved easy to work on. Anyone could hot rod it or swap parts out without hurting it. At one point in time the engine was tested at wide open throttle with no oil. The first time the small block lasted just over an hour. The second time it lasted two! The small block stayed right up competing with other engines because it was so innovating and simple. And with over 90 million built that's also saying something!

It's no mystery that technological advancements has brought new life into the small block. Power levels of the little engine rivaled those of the late 60's and performance was alive again.

The 1990 IROC Camaro had a 2.2 second 0-60 time out of the hole.That put it in a class along with the Corvette and 911 Porsche. To give an example of the the ability of the Tune Port Injected 305's ability in the IROC,it did 0-60 in 6.3. This engine was mated to a 5 sp manual gear box. The Tuned Port 350 mated to a 4 sp automatic in the 1990 IROC did 0-60 in 6.1 seconds. Quarter mile times were both 14.8 seconds,although the 305's speed was 95.4 against the 350's 96 MPH. The 305 did it with better fuel economy. These performance numbers were on par or even better than the performance numbers seen in the 1960's. 1990 would be the last year of the IROC because Chevrolet did not with the International Race Of Champions. and would return to using the Z-28 as their performance platform for the Camaro.

It's no mystery that technological advancements has brought new life into the small block. Power levels of the little engine rivaled those of the late 60's and performance was alive again.

The 1990 IROC Camaro had a 2.2 second 0-60 time out of the hole.That put it in a class along with the Corvette and 911 Porsche. To give an example of the the ability of the Tune Port Injected 305's ability in the IROC,it did 0-60 in 6.3. This engine was mated to a 5 sp manual gear box. The Tuned Port 350 mated to a 4 sp automatic in the 1990 IROC did 0-60 in 6.1 seconds. Quarter mile times were both 14.8 seconds,although the 305's speed was 95.4 against the 350's 96 MPH. The 305 did it with better fuel economy. These performance numbers were on par or even better than the performance numbers seen in the 1960's. 1990 would be the last year of the IROC because Chevrolet did not with the International Race Of Champions. and would return to using the Z-28 as their performance platform for the Camaro.

|

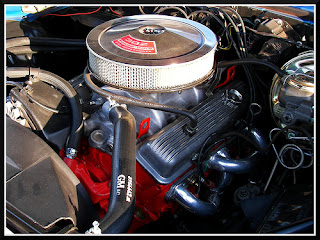

| Example of 305 T.P.I. with Automatic Transmission |

The 305 T.P.I. powered the Caprice of that year and achieved 17 miles to the gallon in the city and 26 on the highway.This was also partly a result of the Caprice being redesigned with a better drag co-efficiency.

The Gen II LT1

IN 1970 Chevrolet built the strongest small block out of the best parts it had at hand. The result was the LT1. The engine grossed 370 HP give or take. The Gen II LT1 would prove to be the most powerful small block Chevy built to date.A re-disigned low rise intake manifold,a new throttle body and optically triggered ignition that was re-located to the front of the engine. High pressure fuel rails feeding both cylinder banks with dual oxygen sensors in each bank of the dual exhaust leads to the most efficient and powerful small block of the 90's. So much so it improved fuel economy by another mile to the gallon over the L98. This engine produced 300 net HP and 330 net LB/FT of torque. Coupled with the a 6 speed manual gear box the Corvette rocketed to a 0-60 time in 4.92 seconds and flew through the quarter mile doing 103.5 mils an hour in 13.7 seconds.

The Gen II LT1

IN 1970 Chevrolet built the strongest small block out of the best parts it had at hand. The result was the LT1. The engine grossed 370 HP give or take. The Gen II LT1 would prove to be the most powerful small block Chevy built to date.A re-disigned low rise intake manifold,a new throttle body and optically triggered ignition that was re-located to the front of the engine. High pressure fuel rails feeding both cylinder banks with dual oxygen sensors in each bank of the dual exhaust leads to the most efficient and powerful small block of the 90's. So much so it improved fuel economy by another mile to the gallon over the L98. This engine produced 300 net HP and 330 net LB/FT of torque. Coupled with the a 6 speed manual gear box the Corvette rocketed to a 0-60 time in 4.92 seconds and flew through the quarter mile doing 103.5 mils an hour in 13.7 seconds.

|

| Gen II 350 LT1 |